195 lb Dry Chemical Gauges G195

$8.25

Description

MATERIALS

- CASE: Stainless Steel

- SOCKET: Brass (with powder paint coating)

- COMPATIBILITY CODE: M

- TEXT: Gauge/Valve Material Compatibility

Gauges have compatibility codes printed on their faces. These are usually the letter ‘A’ or ‘M’ with lines above, below or both above and below the letter. This is to signify the type of valve it can be used on:

- A letter with a line ABOVE AND BELOW it, or NO LINES at all, means the gauge can be used with either brass or aluminum valves

- A letter with a line BELOW it means the gauge can be used on brass valves only

- A letter with a line ABOVE it means the gauge can be used on aluminum only

Do not use a gauge specified for use on a brass valve on an aluminum valve. The contact of the two dissimilar metals will result in galvanic corrosion unless the gauge is coated with epoxy or a similar compound to minimize this risk.

PRINCIPLES OF OPERATION

- BACKGROUND: Older gauges operate using a ‘c-shaped’ Bourdon tube which straightens under pressure and returns to its original form when the pressure drops. The end of the tube was geared to turn the dial. New gauges (after 1964) use a spiral Bourdon tube without a gear.

- Incorrect Pressure Readings: Gauges are calibrated against atmospheric pressure, which is indicated when the gauge reads zero. Thus a cylinder pressure of 100 psi would move the pointer to 100. If there is a slow leak inside the case, however, and the pressure inside the gauge were 100 psi, the gauge would read zero. New gauges have pressure relief devices which relieve case pressure at 50 psi or less. There are many ways of creating leaks and leaks are not the only things that cause gauges to give false readings, so care should be used when installing them

Shipping & Delivery

Zone Métropolitaine (Metropolitan Area)

| PRICES IN USD | |

|---|---|

| Delmas | $ 15 |

| Pétion-Ville | $ 25 |

| Kenscoff | $ 30 |

| Tabarre | $ 20 |

| La Plaine | $ 25 |

| Carrefour | $ 35 |

Zones avoisinantes et Villes de Provinces

| DEPARTMENTS/CITIES | PRICES IN USD |

|---|---|

| ARTIBONITE | |

| Gonaïves | $ 770 |

| Gros Morne | $ 900 |

| Marchand Dessalines | $ 770 |

| Ennery | $ 880 |

| Montrouis | $ 550 |

| Saint-Marc | $ 660 |

| CENTRE | |

| Hinche | $ 660 |

| Mirebalais | $ 550 |

| Thomonde | $ 605 |

| GRAND'ANSE | |

| Beaumont | $ 1210 |

| Corail | $ 1100 |

| Dame Marie | $ 1342 |

| Jérémie | $ 1430 |

| NIPPES | |

| Miragoane | $ 550 |

| NORD | |

| Cap-Haïtien | $ 1430 |

| Limbé | $ 1320 |

| Limonade | $ 1320 |

| Plaisance | $ 990 |

| NORD-EST | |

| Fort-Liberté | $ 1430 |

| Ouanaminthe | $ 1430 |

| Trou du Nord | $ 1430 |

| Terrier Rouge | $ 1430 |

| NORD-OUEST | |

| Jean Rabel | $ 1386 |

| Port-de-Paix | $ 1430 |

| OUEST | |

| Arcahaie | $ 550 |

| Bon-Repos | $ 330 |

| Cabaret | $ 440 |

| Grand-Goave | $ 440 |

| Léogane | $ 385 |

| Petit-Goave | $ 550 |

| SUD | |

| Aquin | $ 770 |

| Camp-Perrin | $ 874.50 |

| Cavaillon | $ 715 |

| Les Cayes | $ 792 |

| Saint-Louis du Sud | $ 1430 |

| SUD-EST | |

| Jacmel | $ 660 |

Related products

Brooks FEC2 Red Vinyl Fire Extinguisher Cover- MEDIUM- 25″ x 16 1/2″

$26.11

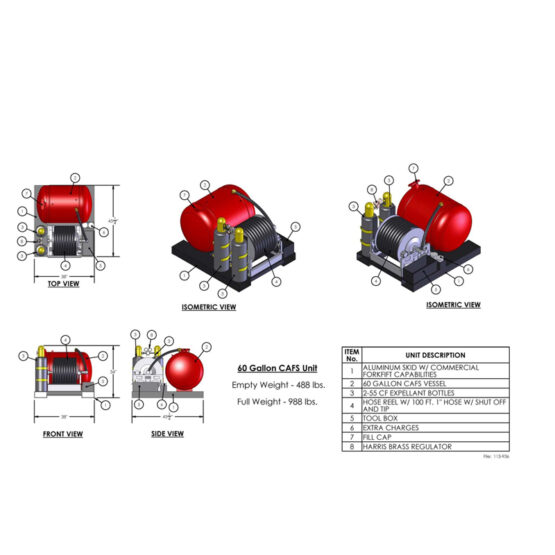

60 Gallon Standard Amerex Compressed Air Foam Skid Units

Applications

Amerex Compressed Air Foam Units provide rapid flame attack for Class A and B hazard areas. CAFS attacks all sides of the fire tetrahedron by smothering the fire with a "foam blanket", thus preventing oxygen from combining with fuel. It diminishes the heat by insulating and reflecting radiant heat, thus preventing excess heat to the fire via a foam barrier. The versatility of these systems have been proven by field tested use in multiple applications. Common high hazard risk areas include:

- Oil and Gas Production Facilities

- Heliports and Helidecks

- Flammable Liquid Storage and Transport

- Fracking Sites

- Mining Operations

- Race Tracks

- Aircraft Hangars

- Rapid Response Vehicles

- Industrial and Municipal Fire Departments / Brigades

- Military Fire Teams

Honeywell – System Sensor SPSCW-CLR-ALERT White Ceiling-Mount SpectrAlert Advance Strobe

$74.80

Brooks Equipment 3651AC Ansul® Hanger Bracket; 15 – 30 lb., Steel

$3.41

System Sensor P2RK 2-Wire Outdoor H/S Multi-Candella, Red

$116.60

- Electrically compatible with existing SpectrAlert products

- Automatic selection of 12- or 24-volt operation at 15 and 15/75 candela

- Plug-in design

- Field selectable candela settings on wall and ceiling units: 15, 15/75, 30, 75, 95, 110, 115, 135, 150, 177, 185

- Same mounting plate for wall- and ceiling-mount units

- Shorting spring on mounting plate for continuity check before installation

- Tamper resistant construction

- Outdoor wall and ceiling products rated from –40°F to 151°F

- Design allows minimal intrusion into the back box

- Horn rated at 88+ dbA at 16 volts

- Rotary switch for horn tone and three volume selections

- Outdoor products UL listed to UL 1638 (strobe) and UL 464 (horn) outdoor requirements

- Outdoor products rainproof per UL 50 (NEMA 3R)

- Compatible with MDL sync module

100lb Dry Chemical Gauges G100

$13.86